Maintaining the health and efficiency of your cooling tower is critical for the system’s optimal performance and helps you avoid costly repairs or downtime. This article explores three proven methods for effective cooling tower maintenance. Implement these strategies to ensure your cooling tower operates at its best, providing efficient cooling and prolonging your equipment’s lifespan. Let’s dive in!

Regular Cleaning

Regular cleaning prevents the build-up of debris, sediment, and contaminants that can hinder the tower’s performance. Follow these steps to keep your cooling tower clean and efficient:

When cleaning, focus on the cooling tower basin. Remove any standing water and scrub the basin thoroughly using a non-abrasive cleaning solution. Pay attention to corners and hard-to-reach areas to eliminate accumulated dirt or algae.

Turn your attention to the tower fill and drift eliminators. These components maximize heat transfer and minimize water loss. Clean them using a high-pressure water spray to remove dirt, scale, or organic growth. Ensure the fill and drift eliminators are free from blockages or obstructions as they can compromise functionality.

Remember to address the tower sump. Remove debris and sediment at the bottom of the sump. This step is crucial to maintain proper water circulation and prevent clogging or reduced flow rates.

Water Treatment

Proper water treatment measures prevent scale, corrosion, and microbial growth, enhancing your cooling tower system’s longevity and efficiency. To combat microbial growth, use biocides. Biocides control bacteria, algae, and other microorganisms thriving in cooling tower systems.

These microorganisms can lead to fouling, reduced heat transfer, and potential health risks. Incorporate appropriate biocides into your water treatment plan to effectively manage microbial growth and maintain a clean and safe cooling tower environment.

Monitor and maintain proper chemical levels. Regularly test and adjust your cooling tower water’s chemical parameters, including biocide concentration, pH, and inhibitor levels. This ensures the water chemistry remains within optimal ranges, preventing scaling, corrosion, and microbiological issues.

Consider collaborating with water treatment professionals. These experts assess your water treatment needs, design a tailored program, and provide guidance on the selection and application of appropriate chemicals.

Inspection and Maintenance Schedule

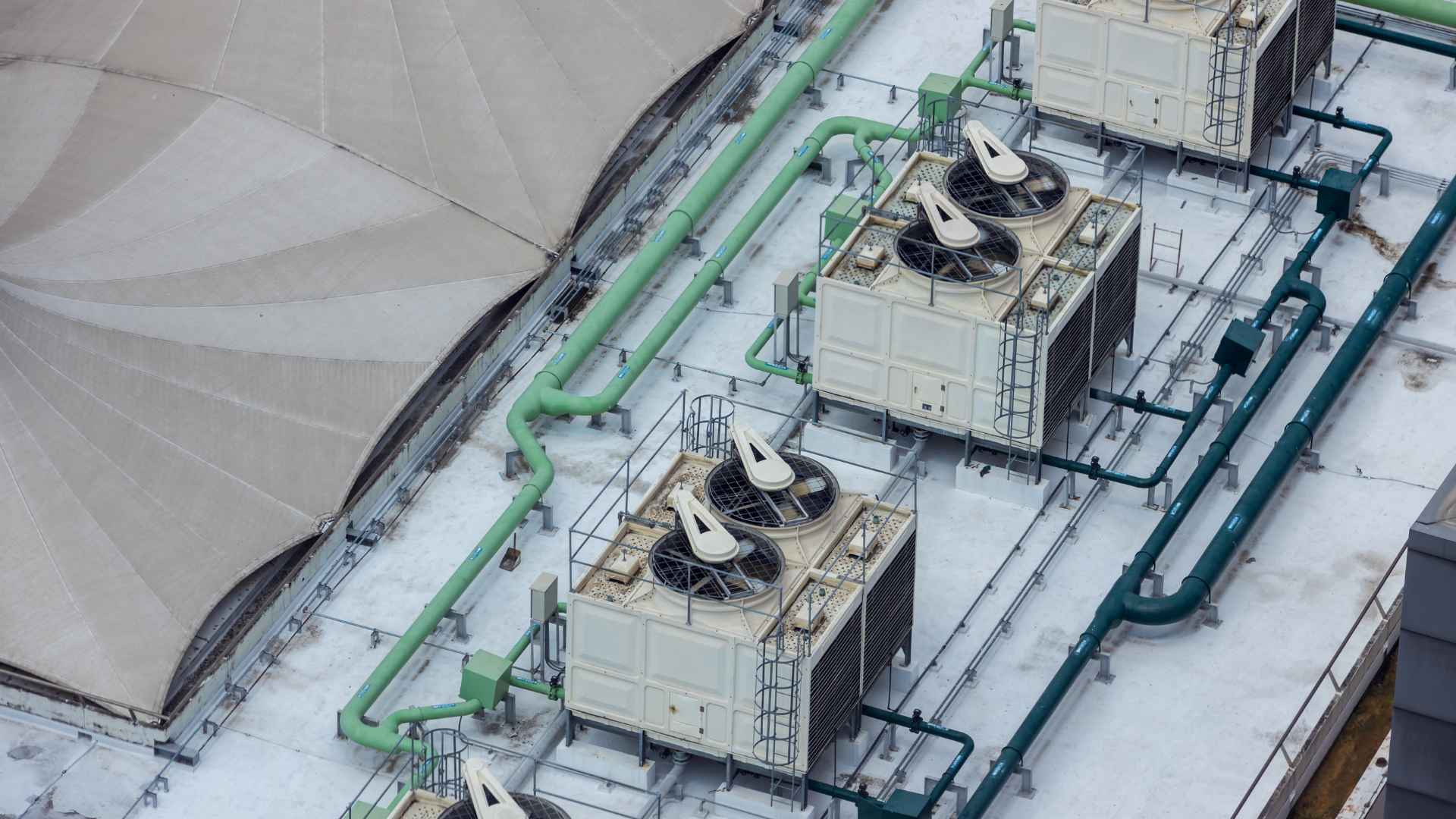

Regularly assess your cooling tower components, paying close attention to motor and fan components. Inspect them for signs of wear, damage, or malfunction. Addressing these issues prevents further damage and potential system failures.

Check for leaks and ensure proper water flow throughout the system. Leaks or blockages hinder the cooling tower’s efficiency and lead to water loss or reduced performance. Detecting and addressing these issues early on is essential for maintaining optimal operation.

It’s recommended you schedule routine maintenance tasks as part of your cooling tower maintenance for your system’s optimal functionality. This includes lubricating bearings, tightening bolts and connections, and cleaning or replacing filters. Adhere to a maintenance schedule to prevent equipment breakdowns and prolong your cooling tower’s lifespan.

During inspections, keep a keen eye out for possible abnormalities or warning signs. Unusual noises, vibrations, or changes in performance indicate underlying problems requiring attention. Promptly address these issues to avoid costly repairs or system downtime.

Get Exceptional Results with Airlogix Commercial HVAC/R

Don’t settle for anything less than exceptional for your cooling tower maintenance. Trust Airlogix Commercial HVAC/R to deliver outstanding results, keeping your cooling tower operating at its best and maximizing its performance. Contact us today and experience the difference.

Bethany Elfaham spearheads AirLogix, a company distinguished for its advanced commercial HVAC/R services. Bethany’s leadership and expertise in mechanical systems have propelled AirLogix to the forefront of HVAC innovations, offering energy-efficient and reliable solutions to businesses. Her focus on sustainable practices and customer-centric service ensures that AirLogix remains a leader in enhancing indoor air quality and operational efficiency for its clients.